CHANNELLOCK XLT™ Series Pliers

XLT™ Series Pliers

![]()

CHANNELLOCK® is celebrating its 136th year of manufacturing high-quality pliers and hand tools. After making pliers for all of these years you’re probably wondering how they can dramatically improve the functionality of a pair of needle-nose pliers, lineman’s pliers or diagonal cutting pliers. Well, they have done it.

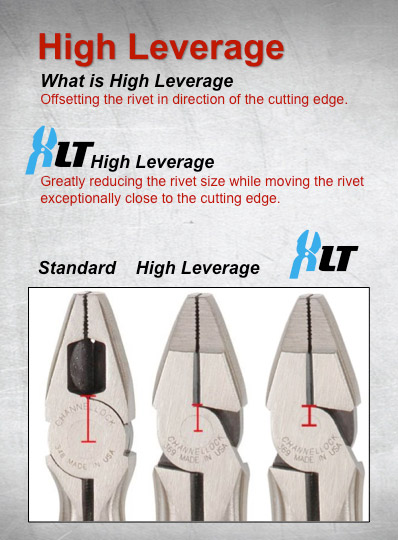

Anyone who has ever tried to cut large-gauge electrical wire knows how tough it can be, sometimes requiring two hands to make the cut. CHANNELLOCK® came up with the ingenious idea of moving the rivet (pivot pin) of the plier joint closer to the cutting jaws, which will increase the leverage and significantly reduces the amount of pressure pounds to make the cut. In one test by IMR Test Labs it required 42 percent less force to make the cut with a similar size product from a competitor without the Xtreme Leverage Technology (XLT™). That truly is a significant difference.

During our product review our volunteer testers put the CHANNELLOCK® XLT series pliers (with the rivet moved closer to the cutting jaws) to the test and immediately noticed a significant difference over other cutting pliers of similar size and price range. We tested more than 25 different sizes and styles of CHANNELLOCK® XLT High Leverage pliers. We tested the traditional blue cushion-grip cutting pliers (the standard style CHANNELLOCK® pliers) as well as the Code Blue® cutting pliers with the oversize blue and red handles with the XLT High Leverage feature and both worked equally well.

Our testers were able to cut wire sizes that normally would require two hands or the added help of using your thigh as added leverage. Every one of our volunteer testers agreed that the CHANNELLOCK® XLT series pliers were a considerable improvement over other pliers they were used to using. It is a rare thing to have all of our testers agree and, when they do, you can bet the product is a good one.

Our testers were able to cut wire sizes that normally would require two hands or the added help of using your thigh as added leverage. Every one of our volunteer testers agreed that the CHANNELLOCK® XLT series pliers were a considerable improvement over other pliers they were used to using. It is a rare thing to have all of our testers agree and, when they do, you can bet the product is a good one.

CHANNELLOCK® has a well-established reputation of making quality products. Their pliers have the “knife and anvil” cutting edges that help maintain alignment of the cutting jaws, which result in a consistent clean cut and the cutting edges are laser heat treated for added durability.

In the 35 years that we’ve been selling CHANNELLOCK® lineman’s pliers, I’ve never seen a pair worn out to the point they could not make the cut. Mark Yoder from Channellock told me that most manufacturers experience a one and a half to two percent return rate (defectives), but CHANNELLOCK’s defective rate is less than one quarter of one percent.

And best of all, CHANNELLOCK® pliers are made right here in the USA. In a time when we are trying to keep people employed in this country it’s always a great feeling to buy and sell quality products made in the USA.

While you are attending one of your wholesaler shows next month (all of the major hardware wholesalers are stocking the CHANNELLOCK® XLT series pliers) stop by the CHANNELLOCK booth and see firsthand what a difference the CHANNELLOCK® XLT series of pliers makes. If you’re like me you won’t really believe it until you actually try it. Your customers will be glad you did.